About Our Company

Welcome to Custom Systems Integration

About CSI

Custom Systems Integration Inc. (CSI) is the largest employee owned Custom Engineering and Manufacturing Services and ATE Systems Integration company in the United States.

CSI is Located in a 20,000 sq ft facility in Binghamton, NY which houses:

- Operations and Support Organizations

- Engineering

- Systems

- Electrical and RF

- Mechanical

- Software

- Separate Production and Integration Areas

- Separate Production and Integration Areas

- Engineering

CSI Advantage

Welcome Custom Systems Integration

Fill Your Resource Voids

When Needed

At CSI, we strive to lead in the design, development and manufacturing of custom test systems and solutions.

We translate the latest technology, incorporating appropriate COTS components into systems and solutions with high value for our customers.

We accomplish this better than anyone else due to our professional engineering, manufacturing and operations staff.

We provide lowest cost systems solutions using a very open and unique mode of engagement.

This unique integrated mode of engagement results from the following company habits and focuses:

- Detailed quotes/proposals

- Quick program/project starts and kick off meetings with our customers

- Weekly progress updates, status reports and conference calls

- Change tolerant program/project management

- Follow up and follow through

Industries We Cover

Custom Systems Integration Inc.

Electronic

Products

Satellites

Aerospace

/Defense

Networks

Medical

RF/Microwave

Design & Development

Resources are available across the US, skills cover all engineering aspects, operating systems/software languages.

CSI’s deep, seasoned staff with direct industry experience is available to complement customer’s staff.

Complete documentation packages (PL, WL, Schematics, Drawings, Gerbers, etc) provided with all deliveries.

- System, System Components and TPS’s

- Fixtures/ITAs/PIAs/Nests

- PWBs

- Software

- Miscellaneous Hardware/Test Boxes

- Cables/Harnesses, Chassis/Panels

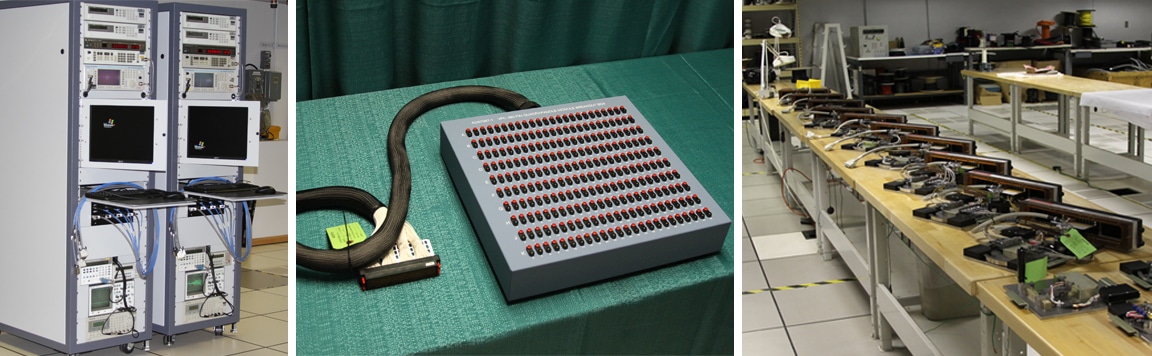

Build To Print

System And Component Build-To-Print (Duplication)

Whether from existing prints or through reverse engineering a system on your floor, CSI can build a functional version of that system. The benefits of CSI’s System and Component Build-to-Print (Duplication) are:

- Best equipment discounts

- Reduce schedule w/CSI stocked parts

- Utilize CSI vast floor space

- CSI procurement resources

- Complete turn-key deliveries

- Work with existing documentation, fill in any holes as appropriate and deliver complete redline packages

- Obsolete and long lead part solutions

- Better utilize customer internal resources

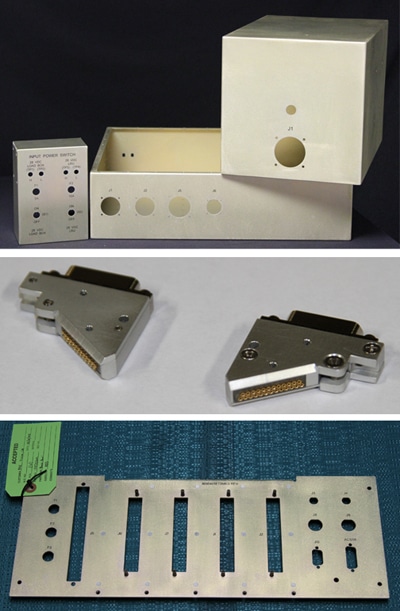

Fixtures & ITAs

Custom Fixtures, ITAs, PIAs and Nests Personalize any Tester

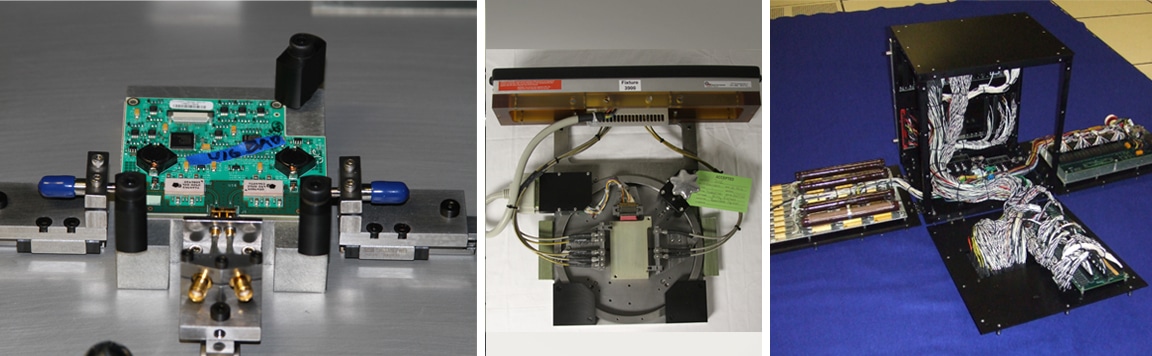

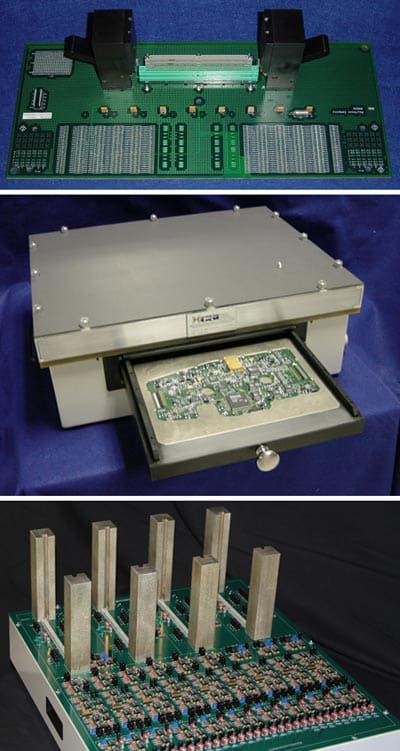

CSI’s team of mechanical, electrical and software engineers can design and build assemblies to mate your device under test to the test system. CSI has designed single-up and multiple-up active and passive fixtures that range from very simple, low-tolerance, manually actuated fixtures to very complex, high-tolerance systems with full automation.

We’ve implemented technology to align 9 micron core single mode fiber to lenses with positioning accuracy to 100 nanometers.

All of our fixtures are delivered with documentation with a focus on human factors and safety. We can optionally provide you with self-test and calibration capabilities as well.

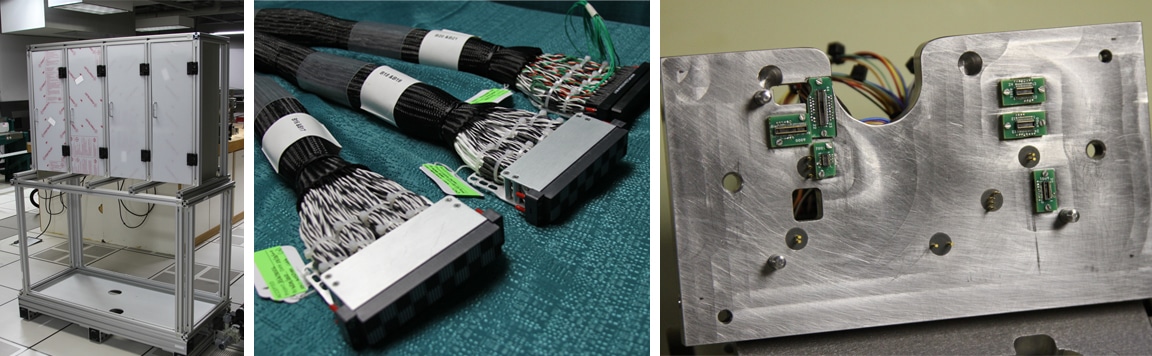

CSI has designed a “EZ” ITA with a low cost quick to manufacture ITA that can mate to any Tester interface. This “EZ” ITA replaces costly larger, formed, welded and bent chassis which cost much more and take more time to manufacture. CSI’s “EZ” ITA incorporates the ability to use hinged or removable panels, mount component sub-plates on all panels and route wiring for easy maintenance. The CSI framed concept can also be used for bench test chassis and rack mount test chassis.

- Simple to complex fixtures

- Manual to fully automated

- Sheet metal, G10, Delrin, Aluminum, Nylon, etc.

- Probing configurations

- Multiple DUTS/UUTs per fixture

- Camera for auto LED processing

- Hydraulic, pneumatic

- Any Photonics component/part

Fabrication & Manufacturing

Complete Systems and System Components

- System and Component Built-To-Print (Duplication)

- Shelves

- Panels

- Cables/Harnesses

- Fixtures/ITAs/PIAs/Nests

- PWBs

- Miscellaneous Hardware/Test Boxes